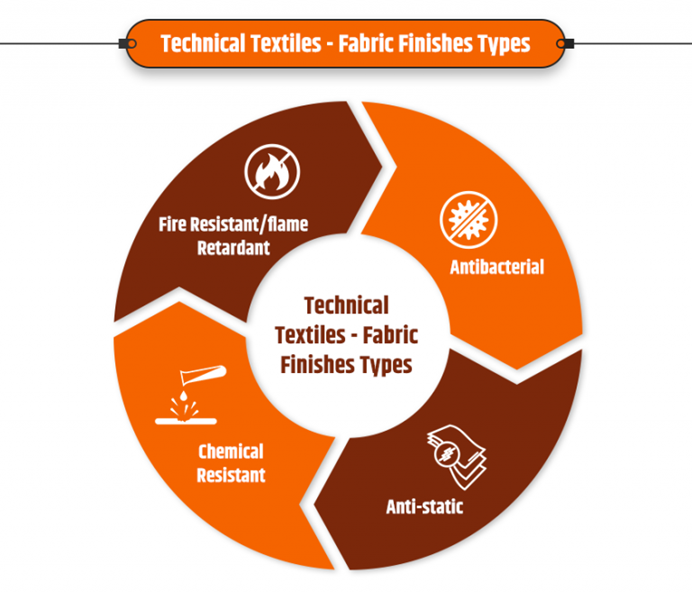

Fabric Finishing: Anti-static finish, Anti-microbial finish, Hydrophilic finish, pre-shrinking finish and so on.

Ever wonder how fabric becomes waterproof? Or why flannel feels so soft? It’s because of fabric finishing and treatments. After many fabrics are woven, they’re taken through physical and chemical processes to add certain qualities, which are what we mean when we say fabric finishing and treatments. For example, they may be treated to make them anti-static, water resistant, or pre-shrinking.

Some fabrics are treated to make them have above properties, we need to add some additives to finish it.

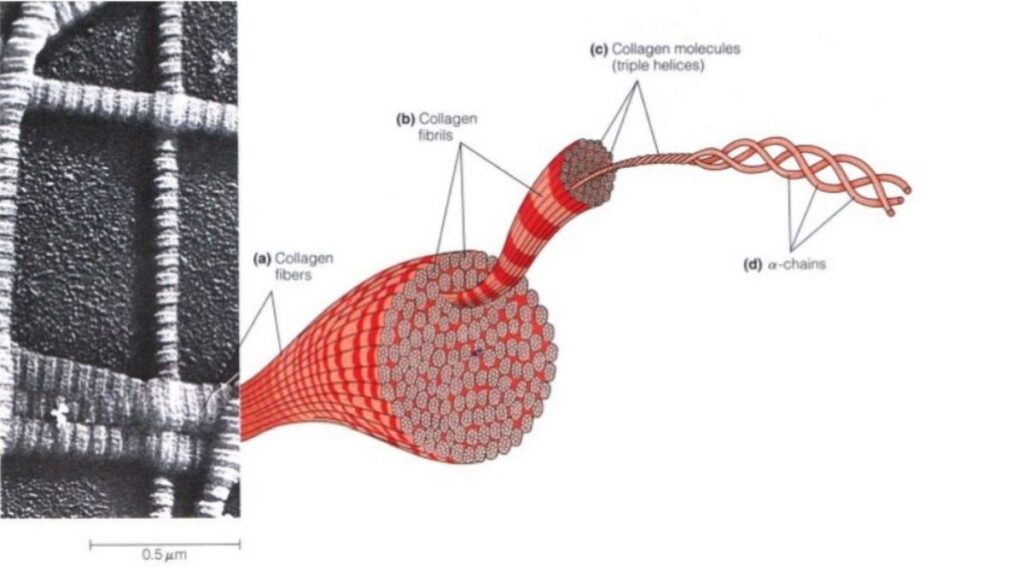

Anti-microbial finish causes the fabric to inhibit the growth of microbes. The humid and warm environment found in textile fibers encourages the growth of the microbes. Infestation by microbes can cause cross-infection by pathogens and the development of odor where the fabric is worn next to the skin. In addition, stains and loss of fiber quality of textile substrates can also take place. With an aim to protect the skin of the wearer and the textile substrate itself, an anti-microbial finish is applied to textile materials.

https://dgysfz.com/?s=microbial

Sanforizing or pre-shrinking prevents a fabric and the produced garment from shrinking after production. This is also a mechanical finish, acquired by feeding the fabric between a roller and rubber blanket, in such a way the rubber blanket compresses the weft threads and imparts compressive shrinkage.

Anti-static finish prevents dust from clinging to the fabric. Anti-static effective chemicals are largely chemically inert and require Thermasol or heat treatment for fixing on polyester fabrics. Polyether agents have been found to be useful but should not affect the dye-equilibrium on fiber, lest they impair the rubbing fastness.[citation needed] In general, Thermasol anti-static agents also have a good soil release action, which is as permanent as the anti-static effect. Anti-static finishes may also be of polyamide type, being curable at moderate temperatures.

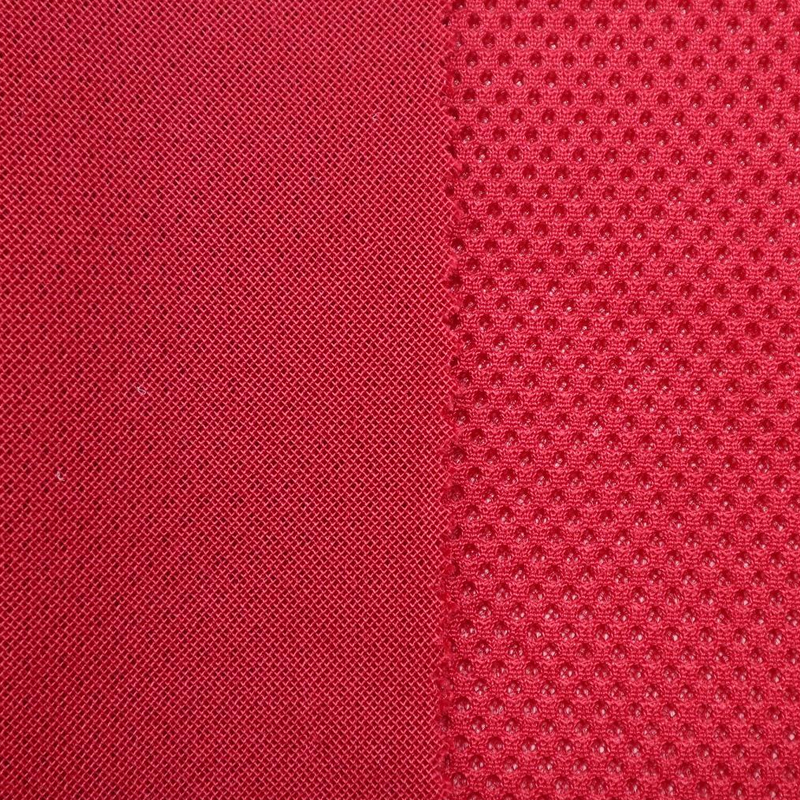

Hydrophilic finishes compensate for lower moisture and water absorption capacity in synthetic fiber materials, which become uncomfortable in contact with skin. Certain products, based on modified (oxy-ethylated) polyamides, make the fabric more pleasant by reducing the cohesion of water so that it spreads over a larger area and thus evaporates more readily.

Waterproof finish is to coat the fabric so that neither water nor air can pass through. Water-repellent finish makes the surface of the fiber hydrophilic to hydrophobic. The fabric is breathable and not easily wetted by water.

https://dgysfz.com/?s=waterproof