Dive into the fascinating realm of single jersey fabrics, known for their versatility and widespread use in the textile industry. Discover the characteristics, manufacturing processes, applications, and creative possibilities of this popular fabric type. From apparel to home textiles and beyond, explore the diverse applications and innovative techniques that make single jersey fabrics a staple in the fashion and design world.

Introduction to Single Jersey Fabrics

1.1 What are Single Jersey Fabrics?

Single jersey fabrics are a versatile and widely used type of knitted fabric. They belong to the category of weft-knitted fabrics, where the yarns run horizontally across the fabric. Single jersey fabrics are known for their distinct v-shaped wales on one side and looped stitches on the other. These fabrics are commonly used in fashion and apparel due to their stretchability, comfort, and ease of production.

1.2 Characteristics and Properties

Single jersey fabrics possess several distinct characteristics and properties that contribute to their popularity. Here are some key features:

- Stretch and Elasticity: Single jersey fabrics exhibit excellent stretch and recovery properties, allowing them to comfortably conform to the body’s movements. This characteristic makes them ideal for garments that require flexibility and freedom of motion.

- Breathability: The structure of single jersey fabrics allows for good air circulation, enhancing breathability and moisture management. This property helps to keep the wearer cool and comfortable, making single jersey fabrics suitable for activewear and summer garments.

- Softness and Comfort: Single jersey fabrics are typically made from fine yarns, resulting in a soft and smooth texture that feels pleasant against the skin. The looped stitches on the fabric’s backside contribute to its comfort and make it lightweight.

- Versatility: Single jersey fabrics come in various weights and fiber compositions, offering versatility in terms of design possibilities. They can be produced using natural fibers like cotton, wool, or silk, as well as synthetic fibers like polyester or nylon. This versatility allows for a wide range of applications across different industries.

- Easy Care: Single jersey fabrics are generally easy to care for and maintain. They are machine washable and tend to resist wrinkling, making them convenient for everyday wear.

Manufacturing and Construction

2.1 Production Methods

Single jersey fabrics are primarily produced using circular knitting machines, although flat knitting machines can also be used. Circular knitting machines create tubular fabrics that are later cut and opened to form flat fabric panels. These machines have multiple needles arranged in a circular configuration, which knit continuous rows of stitches.

The production process involves feeding the yarns into the knitting machine, where the needles interlock the yarns to create the fabric structure. The direction and tension of the yarns determine the fabric’s stretch and drape properties. The fabric is then dyed, finished, and prepared for use in various applications.

2.2 Types of Yarns Used

Single jersey fabrics can be made from a wide range of yarn types, each offering unique characteristics and properties. Common yarns used in single jersey fabric production include:

- Cotton: Cotton yarns are popular due to their breathability, softness, and ability to absorb moisture. Cotton single jersey fabrics are comfortable to wear and widely used in casual apparel.

- Polyester: Polyester yarns are known for their durability, colorfastness, and resistance to wrinkling. Polyester single jersey fabrics are often used in activewear and sportswear due to their moisture-wicking and quick-drying properties.

- Wool: Wool yarns provide insulation, warmth, and natural moisture-wicking properties. Single jersey fabrics made from wool are suitable for winter garments and layering pieces.

- Blends: Yarn blends, such as cotton-polyester or wool-acrylic, combine the properties of different fibers to create fabrics with enhanced characteristics. Blended yarns are commonly used to improve the durability, comfort, and performance of single jersey fabrics.

2.3 Knitting Techniques

Various knitting techniques can be employed in the production of single jersey fabrics, allowing for different visual effects and fabric structures. Some common knitting techniques used in single jersey fabric manufacturing include:

- Plain Knit: The most basic and commonly used knitting technique for single jersey fabrics is the plain knit. It creates a fabric with a smooth face and looped stitches on the reverse side.

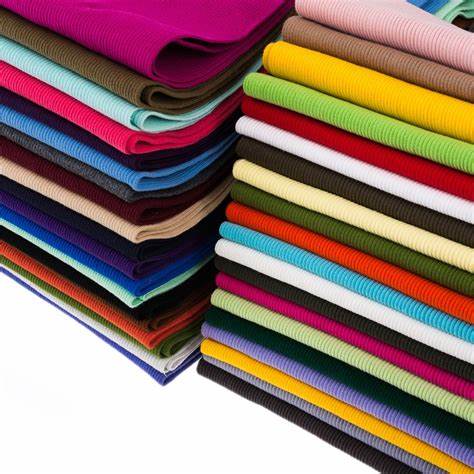

- Rib Knit: Rib knitting involves alternating knit and purl stitches to create raised vertical columns of stitches. This technique results in a fabric with a textured surface and excellent stretch in both length and width.

- Jacquard Knit: Jacquard knitting enables the creation of intricate patterns and designs on single jersey fabrics. By manipulating individual needles, different colors and stitches can be introduced, resulting in complex patterns and motifs.

- Interlock Knit: Interlock knitting produces a double-layered fabric with a smooth surface on both sides. This technique creates a stable fabric with good recovery and reduced curling at the edges.

Performance and Functional Advantages

3.1 Stretch and Elasticity

One of the key advantages of single jersey fabrics is their exceptional stretch and elasticity. The knitted structure allows the fabric to stretch in both width and length, providing a comfortable fit and ease of movement. This property makes single jersey fabrics ideal for garments that require flexibility, such as activewear, sportswear, and body-hugging apparel. The fabric’s ability to bounce back to its original shape ensures that it retains its form even after repeated stretching and wearing.

3.2 Breathability and Moisture Management

Single jersey fabrics offer excellent breathability and moisture management properties. The structure of the fabric allows air to circulate, promoting ventilation and reducing the risk of overheating. This makes single jersey fabrics particularly suitable for warm weather clothing and active wear. Additionally, the inherent moisture-wicking properties of certain fibers, such as polyester or blends with synthetic fibers, help to draw moisture away from the body, keeping the wearer dry and comfortable during physical activities.

3.3 Drape and Comfort

Single jersey fabrics are renowned for their drape and comfort. The lightweight nature of the fabric, combined with its fluidity, allows it to drape gracefully and contour to the body’s curves, enhancing the garment’s overall aesthetic. The softness and smoothness of single jersey fabrics further contribute to their comfort, making them pleasant to wear against the skin. Whether used in casual t-shirts or elegant dresses, these fabrics offer a comfortable and luxurious feel.

Applications in Fashion and Apparel

4.1 T-Shirts and Tops

T-shirts and tops are among the most common applications of single jersey fabrics in the fashion industry. The stretch and drape of single jersey fabrics make them ideal for creating comfortable and well-fitting garments. Whether it’s a basic everyday t-shirt or a stylish blouse, the versatility of single jersey fabrics allows for a wide range of designs, patterns, and colors. The breathability of these fabrics also adds to their popularity in creating lightweight and breathable summer tops.

4.2 Dresses and Skirts

Single jersey fabrics are also widely used in the production of dresses and skirts. The stretch and draping capabilities of these fabrics contribute to creating flattering silhouettes and comfortable fits. Single jersey dresses can range from casual and flowy maxi dresses to more structured bodycon dresses, depending on the weight and texture of the fabric. Skirts made from single jersey fabrics offer ease of movement while maintaining a polished and feminine look.

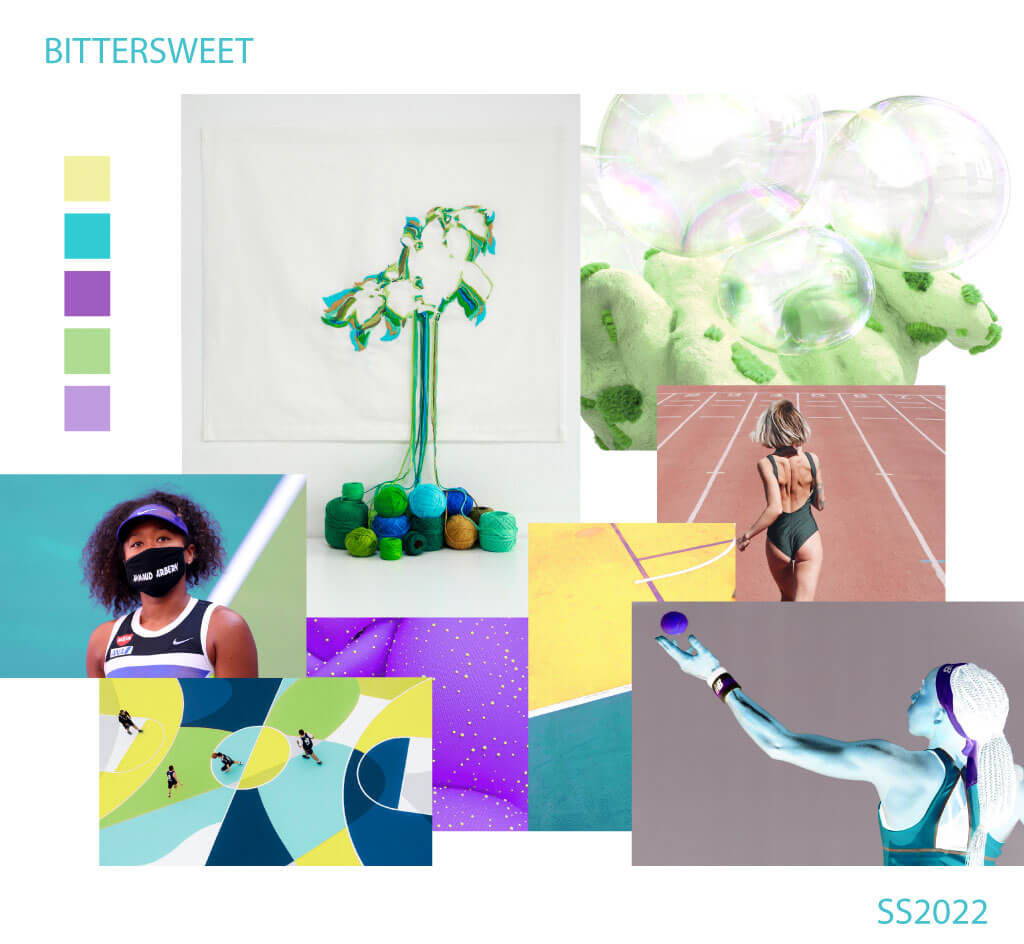

4.3 Activewear and Sportswear

The performance advantages of single jersey fabrics make them a popular choice for activewear and sportswear. These fabrics offer excellent stretch and recovery, allowing for unrestricted movement during physical activities. They also provide moisture-wicking properties to keep the wearer dry and comfortable during workouts. Single jersey fabrics are used in the production of leggings, yoga pants, athletic tops, and other sportswear garments that require both comfort and functionality.

Home Textiles and Interior Design

5.1 Bedding and Linens

Single jersey fabrics find applications beyond fashion and apparel in the realm of home textiles. Due to their softness and breathability, these fabrics are used in the production of bed sheets, pillowcases, and duvet covers. The stretch of single jersey fabrics also contributes to a snug fit on mattresses, ensuring a comfortable sleep experience. The wide variety of colors and patterns available in single jersey fabrics allows for versatile choices to match any bedroom decor.

5.2 Upholstery and Cushions

In interior design, single jersey fabrics can be utilized for upholstery and cushions. The stretch and elasticity of these fabrics make them suitable for covering furniture pieces, providing a comfortable and flexible seating experience. The soft texture of single jersey fabrics adds a cozy touch to sofas, chairs, and ottomans. Additionally, single jersey fabric cushions can be used to introduce pops of color and patterns into interior spaces.

5.3 Curtains and Drapes

Single jersey fabrics can also be employed for curtains and drapes, offering a lightweight and breezy alternative to heavier fabrics. These fabrics allow natural light to filter through while providing a certain level of privacy. The fluid drape of single jersey fabrics adds an elegant and relaxed aesthetic to windows, creating a comfortable and inviting ambiance within a room.

Innovations and Sustainable Practices

6.1 Technological Advancements

The textile industry is continually evolving, and technological advancements have had a significant impact on the production and innovation of single jersey fabrics. Advancements in knitting machines, such as computerized knitting systems, have improved the precision and efficiency of fabric production. These machines allow for the creation of intricate patterns, designs, and textures on single jersey fabrics. Additionally, digital printing techniques have revolutionized the way patterns and colors are applied to fabrics, enabling greater customization and design possibilities.

6.2 Sustainable Production Methods

As sustainability becomes an increasingly important consideration in the textile industry, efforts are being made to incorporate eco-friendly practices in the production of single jersey fabrics. Sustainable production methods include:

- Use of organic and recycled fibers: Single jersey fabrics can be manufactured using organic cotton or recycled polyester yarns, reducing the environmental impact associated with conventional fiber production.

- Water and energy efficiency: Manufacturers are implementing water and energy-saving technologies in the production process, minimizing resource consumption and reducing carbon emissions.

- Chemical and dye management: The adoption of eco-friendly dyes and reduced chemical usage in fabric finishing processes helps to minimize environmental pollution.

- Waste reduction and recycling: Efforts are being made to reduce fabric waste during production and explore recycling options for post-consumer fabric waste, closing the loop and reducing the industry’s environmental footprint.

6.3 Future Trends

The future of single jersey fabrics holds exciting possibilities. Here are some emerging trends to watch out for:

- Smart Textiles: Integration of technology into textiles opens up opportunities for the development of smart single jersey fabrics. These fabrics can incorporate features such as moisture-wicking sensors, thermoregulation, and even embedded electronics for wearable technology applications.

- Sustainable Innovations: The focus on sustainability will drive further innovations in single jersey fabric production. This includes the exploration of new eco-friendly fibers, development of biodegradable materials, and advancements in dyeing and finishing processes to minimize environmental impact.

- Performance Enhancements: Research and development efforts will continue to improve the performance properties of single jersey fabrics. This includes enhancing stretch and recovery capabilities, moisture management, and durability, making them even more suitable for diverse applications.

Creative Possibilities and DIY Projects

7.1 Textile Crafts and DIY Fashion

Single jersey fabrics provide ample opportunities for textile crafts and DIY fashion projects. Individuals with a creative inclination can explore various techniques such as fabric painting, tie-dyeing, block printing, or embroidery to personalize single jersey fabrics. These fabrics can be transformed into unique garments, accessories like scarves and headbands, or even home decor items like wall hangings or table runners.

7.2 Customizing Single Jersey Fabrics

Customization is a growing trend, and single jersey fabrics offer the perfect canvas for personal expression. Consumers can opt for custom-printed single jersey fabrics featuring their own designs or choose from a wide range of patterns and motifs available online. This allows for the creation of one-of-a-kind garments, ensuring uniqueness and individuality.

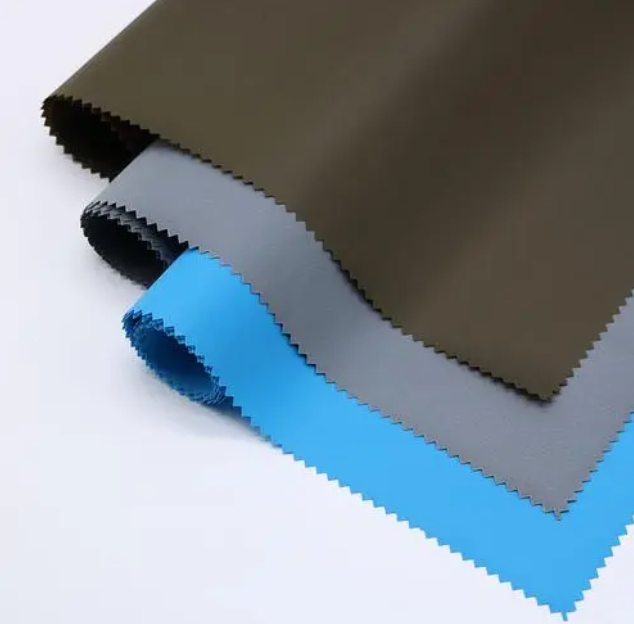

7.3 Hybrid Fabrics and Experimental Techniques

Single jersey fabrics can be combined with other materials to create innovative hybrid fabrics. This opens up possibilities for unique textures, structures, and performance properties. Hybrid fabrics can be achieved through techniques like fabric bonding, laminating, or incorporating unconventional materials such as metal, leather, or plastic. These experimental techniques push the boundaries of traditional fabric applications and pave the way for innovative fashion and design concepts.

In conclusion, single jersey fabrics offer a versatile world of possibilities. From their manufacturing and construction techniques to their performance advantages and applications in fashion, apparel, and interior design, these fabrics continue to be a staple in various industries. With advancements in technology, sustainable practices, and creative DIY projects, the future of single jersey fabrics looks promising, catering to the demands of both comfort-conscious consumers and environmentally conscious individuals.