Demystifying the knitting factory: behind the production of fashion

Overview: The knitting factory is an important part of the fashion industry, responsible for the production of various knitted fabrics, finished products and accessories. The operation of these factories may be mysterious and foreign to many people. In this article, we go behind the scenes of knitting factories and how they contribute to the fashion industry.

1》Operation process of knitting factory

2》Equipment and technology of knitting factory

3》The contribution of knitting factories to the fashion industry

Operation process of knitting factory

The operating process of a knitting factory involves several stages, from design to finished product. Here’s a general overview of the process:

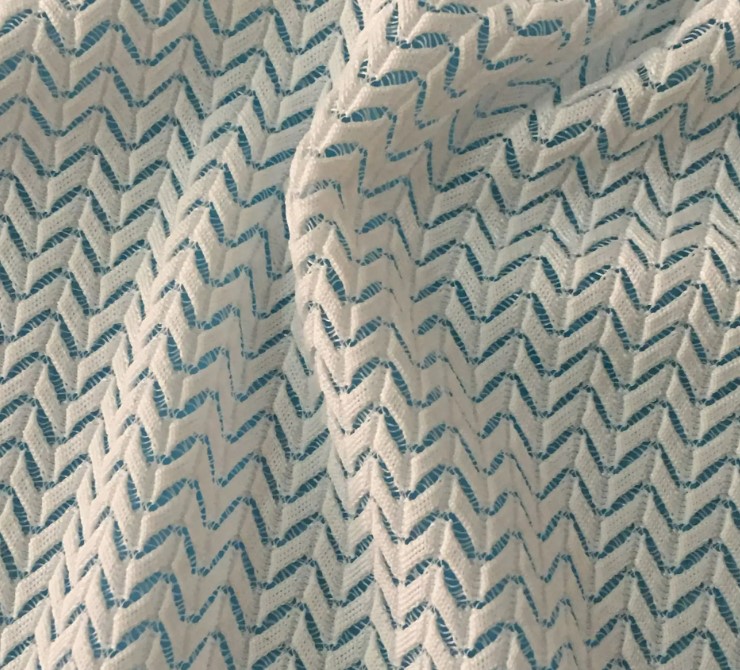

- Design: The design team creates fabric samples and sends them to the factory for knitting.

- Knitting: The factory uses specialized equipment to weave the yarns into fabrics or finished products according to the design requirements.

- Finishing: After the knitting is completed, the fabric or finished product undergoes a series of processing processes such as finishing, washing, drying, and sewing.

- Finished Product: The final product is a fashion item, such as a sweater, hat, or scarf.

The knitting process involves creating fabric samples, which are then sent to the factory for knitting. The factory uses specialized equipment to weave the yarns into fabrics or finished products according to the design requirements. Once the knitting is completed, the fabric or finished product undergoes a series of processing processes such as finishing, washing, drying, and sewing. Finally, the finished product is a fashion item, such as a sweater, hat, or scarf.

It’s important to note that the specific processes and equipment used in a knitting factory can vary depending on the type of fabric being produced and the desired quality of the finished product. Some factories may use computer-controlled knitting machines, while others may use more traditional methods. Additionally, some factories may specialize in producing certain types of fabrics, such as cotton, wool, or synthetic fibers.

Equipment and technology for knitting factories

The equipment and technology used in the knitting factory is also very important. The quality and efficiency of the machine will directly affect the production efficiency and the quality of the finished product. Generally speaking, knitting factories will be equipped with professional equipment such as high-speed knitting machines, computer-controlled knitting machines and circular knitting machines. And these equipments require technicians to adjust and maintain to ensure the normal operation of the production line.

Contribution of Knitting Factory to Fashion Industry

Knitting factories play a vital role in the fashion industry. They can not only manufacture fashion items, but also produce fabrics of various materials and styles, providing more choices for designers and fashion brands. In addition, the high-efficiency production and flexibility of the knitting factory can also meet the needs of fashion brands to quickly respond to the market.