Textile mills are industrial facilities that play a significant role in the production of fabrics and textiles. They are responsible for transforming raw materials, whether natural or synthetic fibers, into various textile products that we use in our everyday lives. These products range from clothing and household linens to carpets and industrial fabrics. Textile mills are crucial components of the textile industry, a sector that spans the globe and employs millions of people. In this blog post, we will explore the operations, processes, and machinery involved in textile mills and their importance in the textile supply chain.

The Processes in Textile Mills

- Spinning: The spinning process involves converting fibers, such as cotton or wool, into yarn. This is typically done using spinning machines that draw and twist the fibers to form continuous threads of yarn.

- Weaving: Weaving is the process of interlacing the yarns to create a fabric. This is done on looms, where the warp (longitudinal) and weft (crosswise) threads are interlaced to form a woven fabric.

- Knitting: Knitting is an alternative method of fabric formation, where yarns are interlooped to create knitted fabrics. Knitting machines are used to produce various types of knitwear.

- Dyeing: After the fabric is woven or knitted, it may undergo dyeing to add color. Dyeing machines apply dyes to the fabric, giving it the desired hue.

- Printing: Textile mills can also have printing facilities, where designs and patterns are applied to the fabric using printing techniques.

The Machinery in Textile Mills

- Looms: Looms are essential machines used in weaving. They come in various types, such as shuttle looms, rapier looms, and air jet looms, and are used to create different types of woven fabrics.

- Knitting Machines: Knitting machines are used to produce knitted fabrics. They can vary in complexity, from simple hand-knitting machines to computerized circular knitting machines.

- Dyeing Machines: Dyeing machines are designed to apply dyes to the fabric evenly. They come in various types, including beam dyeing machines, jig dyeing machines, and continuous dyeing machines.

- Printing Machines: Printing machines are used to apply designs and patterns to the fabric. Common printing methods include rotary screen printing, digital printing, and heat transfer printing.

Importance of Textile Mills

Textile mills play a vital role in the textile industry, producing a wide range of textile products that are essential to our daily lives. The clothing we wear, the towels we use, the carpets in our homes, and the curtains that adorn our windows are all manufactured by textile mills. These mills are not only a significant contributor to the economy but also create employment opportunities and drive technological advancements in the textile sector.

The textile industry is one of the oldest and largest industries in the world, providing employment to millions of people across the globe. Textile mills are the backbone of this industry, producing high-quality fabrics that are used in various applications. The products produced by textile mills are not only used in the domestic market but also exported to other countries, contributing to the country’s foreign exchange earnings.

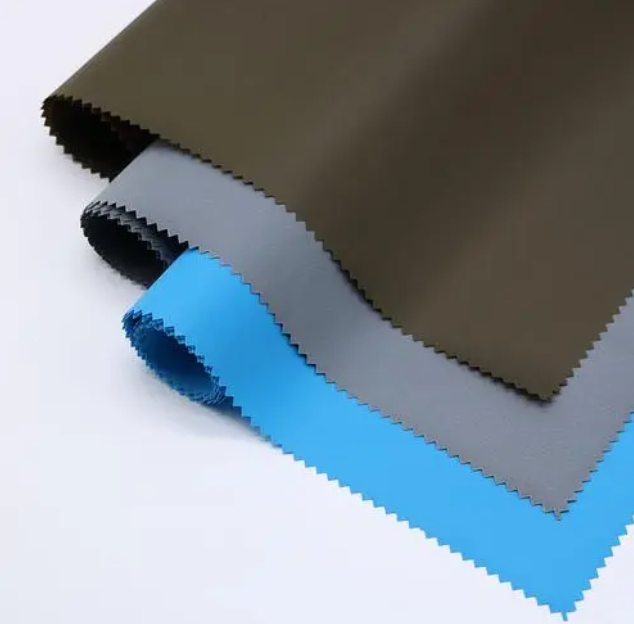

In addition to their economic significance, textile mills also play a crucial role in fostering technological advancements in the textile sector. They invest heavily in research and development, exploring new technologies and techniques to improve the quality and efficiency of their products. This has led to the development of innovative textile products such as wrinkle-resistant fabrics, water-repellent fabrics, and smart fabrics that can adjust to changing temperatures and environments.

Moreover, textile mills are also committed to sustainability, adopting environmentally friendly practices in their production processes. They use eco-friendly materials, reduce waste, and implement energy-efficient measures to minimize their carbon footprint. This not only helps to protect the environment but also reduces the cost of production, making their products more competitive in the market.

Textile mills also play a vital role in promoting social responsibility. They provide employment opportunities to people from diverse backgrounds, creating a diverse and inclusive work environment. They also invest in community development initiatives, supporting education, healthcare, and other social welfare programs in the communities where they operate.

In conclusion, textile mills are the backbone of the textile industry, producing a vast array of textile products that are integral to our daily lives. They contribute significantly to the economy, create employment opportunities, foster technological advancements, and promote sustainability and social responsibility. Their role in society is multifaceted, and their impact on the textile industry and the economy as a whole is undeniable.

Ensuring Quality and Standards

Quality control is paramount in textile mills to ensure that the products meet the desired standards. Stringent testing procedures are carried out to check the strength, colorfastness, and durability of the fabrics. Compliance with safety and environmental regulations is also a crucial aspect of textile mill operations.

Conclusion

Textile mills play a crucial role in the textile industry, producing fabrics and textiles that are essential in our daily lives. They perform processes such as spinning, weaving, knitting, dyeing, and printing to create a wide range of textile products. With the aid of sophisticated machinery and rigorous quality control measures, textile mills produce high-quality fabrics and contribute to the economic growth of nations. As consumers, we can appreciate the significance of textile mills as we use the diverse range of textile products they create in our homes, workplaces, and communities.