Polyester and nylon fabrics have a lot in common. They’re both lightweight materials made from synthetic fibers. And they’re both very popular options for sportswear.

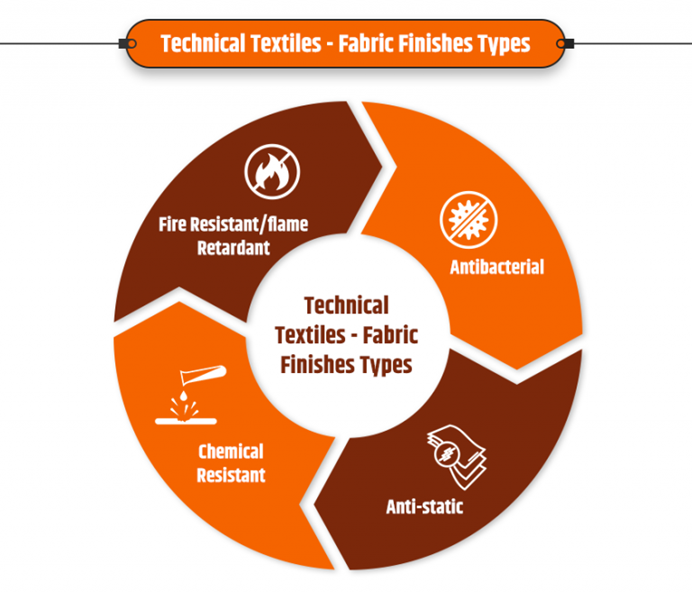

That’s down to their durability – which is much better than that of natural fibers. And how well they respond to post-finishing processes that enhance their function.

But there is also a difference between polyester and nylon fabrics. Understanding how their characteristics differ will help you to decide which material is most suited for the clothing you’re creating.

But first…

How are polyester and nylon fibers made?

Nylon (also known as polyamide in Europe) was first created in 1935 and shot to fame in the form of nylon stockings. Polyester was hot on nylon’s heels, hitting the market in the 1940s.

Both fibers are plastic compounds derived from petroleum. They were designed to be stronger, lighter and more durable than the natural fabrics they came to replace.

But how are polyester and nylon made? The process is very similar for both of these synthetic materials.

Manufacturers take small plastic pellets (about the same size and color as a grain of rice). They melt them and pass the molten solution through a spinneret – a kind of wheel with lots of tiny holes in it.

Plastic strands of different thicknesses and lengths are created. These fibers can then be used as they are to create garments or combined to make thicker threads.

What is the difference between polyester and nylon?

Feel & performance

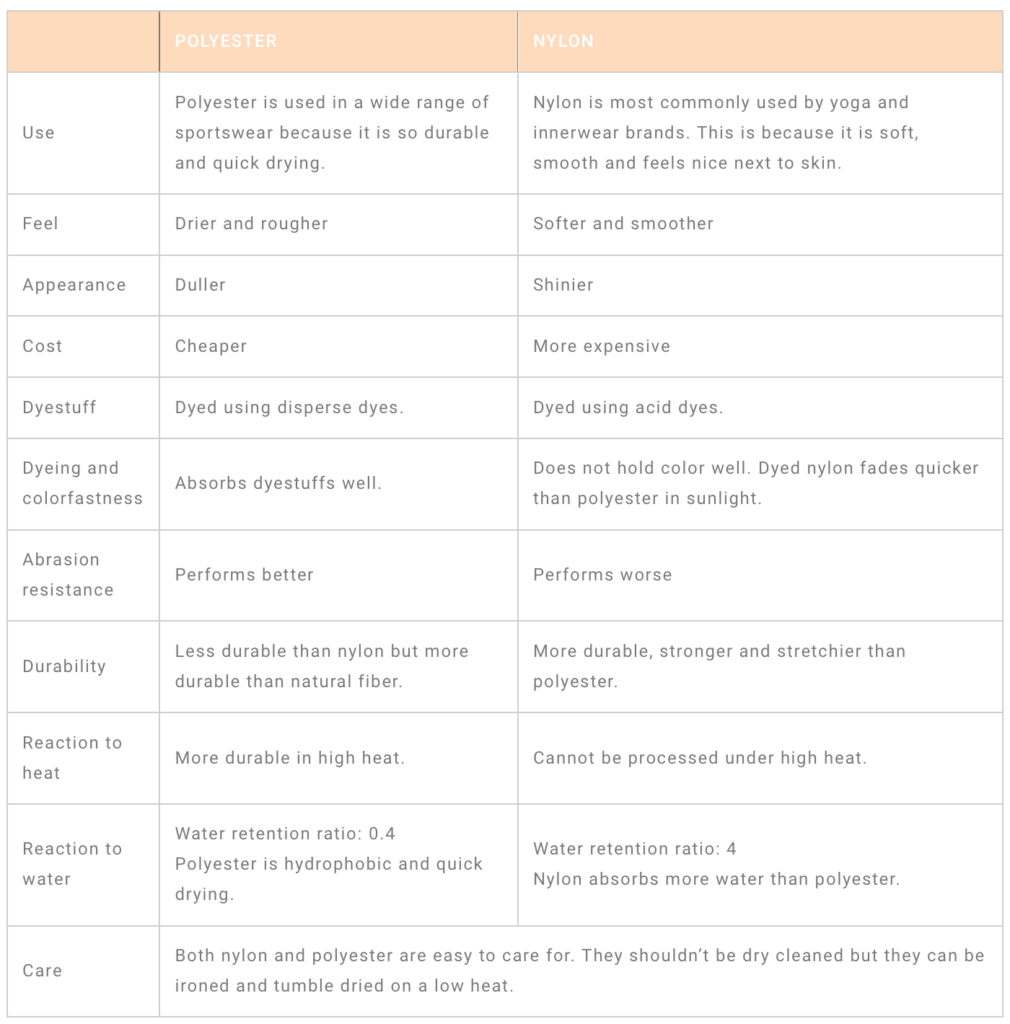

Nylon was created as an alternative to silk, which explains its soft and silky feel. It is also shinier and stretcher than polyester.

Polyester is a generally a rougher, duller fabric. However, modern manufacturing practices have improved the feel of polyester. You can now find polyester that mimic the softness of cotton and isn’t so close to the feel of nylon.

You’ll also find polyester blended with other fibers, like cotton and rayon. This means the yarn has all the great features of polyester at a more affordable price.

Dyeing

Disperse dyes are used to color polyester whilst acid dyes are used to color nylon.

Polyester responds to the dyeing process much better than nylon. Dyes are absorbed well and polyester has good color fastness.

Cationic-dyeable (or CD) polyester is a modified polyester. This type of polyester can be dyed in a different way, giving richer and more vivid color.

Nylon is trickier to work with, which makes dyeing nylon a job reserved for very best professionals.

Dyes are sometimes absorbed in an uneven way across nylon fabric, creating unwanted striping.

And nylon isn’t particularly colorfast either. Under UV rays, dyed nylon fades more quickly than polyester.

In cases where nylon and polyester fibers have been blended, dyeing creates a two-tone effect. You can use acid dye, which the nylon will absorb, and the polyester won’t. Or disperse dye, which nylon absorbs to a lesser extent.

Durability

Both nylon and polyester rate well for strength and durability. But when we make a direct comparison, nylon is stronger and stretcher than polyester, meaning garments made from nylon should last longer.

Nylon falls slightly when it comes to abrasion resistance. This material pills more easily than polyester. Whilst this doesn’t weaken the garment, it will tend to look older more quickly.

Reaction to water

When nylon gets wet it absorbs water and can expand up to 3.5%. So when you’re sweating or working out in the rain, it will take longer for nylon to dry.

Polyester, in comparison, is much less absorbent. It’s a hydrophobic fabric, which means any water is thrust to the surface of the garment, where it is able to evaporate. This makes it great for high-intensity sports where lots of perspiration is a given.

Reaction to heat

Next up. How do these two fabrics cope in the face of heat?

Polyester is the more durable option. It actually needs high heat to absorb dyes. This means it’s a reliable option for sublimation or digital print.

Nylon, on the other hand, can’t be processed under high heat so heat transfer printing is a much more delicate process.

Care

Both fabrics are extremely easy to care for. They don’t wrinkle, stretch or shrink. And they’re not susceptible to mold, mildew or staining either.

When caring for polyester or nylon, a standard washing machine cycle will do. They shouldn’t be dry cleaned. Nor should they be ironed or tumble dried on a high heat. For polyester or nylon with wicking properties, fabric softener should also be avoided.

So which is best? Polyester or nylon?

Nylon and polyester each have their own strengths. Which material is best suited to your project will depend upon the end use and the fabric design.

The silky feel of nylon is hard to beat, which is why nylon is the preferred choice for yoga and underwear brands. But whilst nylon is softer and stronger, polyester dries faster, dyes more easily and is less likely to pill.

These are all reasons why polyester is a popular option for garments used in sports like running, basketball, soccer, and football.

Nevertheless, technological advances are improving both fabrics. For example, polyester yarn is becoming softer. And with a wicking finish, Nylon can take away moisture and dry more quickly.

Taiwanese fabric manufacturers are at the forefront of these changes and the region boasts some of the best synthetic filament production in the world. Manufacturers’ expertise in fine denier filament along with nylon dyeing and printing, has made them the go-to option for many global, big-name brands.

We hope this article has explained the difference between polyester and nylon fabrics for you. If you’re ready to start sourcing the very best polyester or nylon fabrics for your project, look at the Fufang product page or get in touch to find out more.