Fabric with mesh shaped holes is called mesh cloth. Different mesh fabrics can be woven with different equipment, mainly organic mesh fabrics and knitted mesh fabrics

Woven mesh cloth is a type of fabric that is made by weaving or knitting yarns to create a mesh-like structure. It is a versatile fabric that can be used for a variety of applications, including clothing, home textiles, and industrial uses.

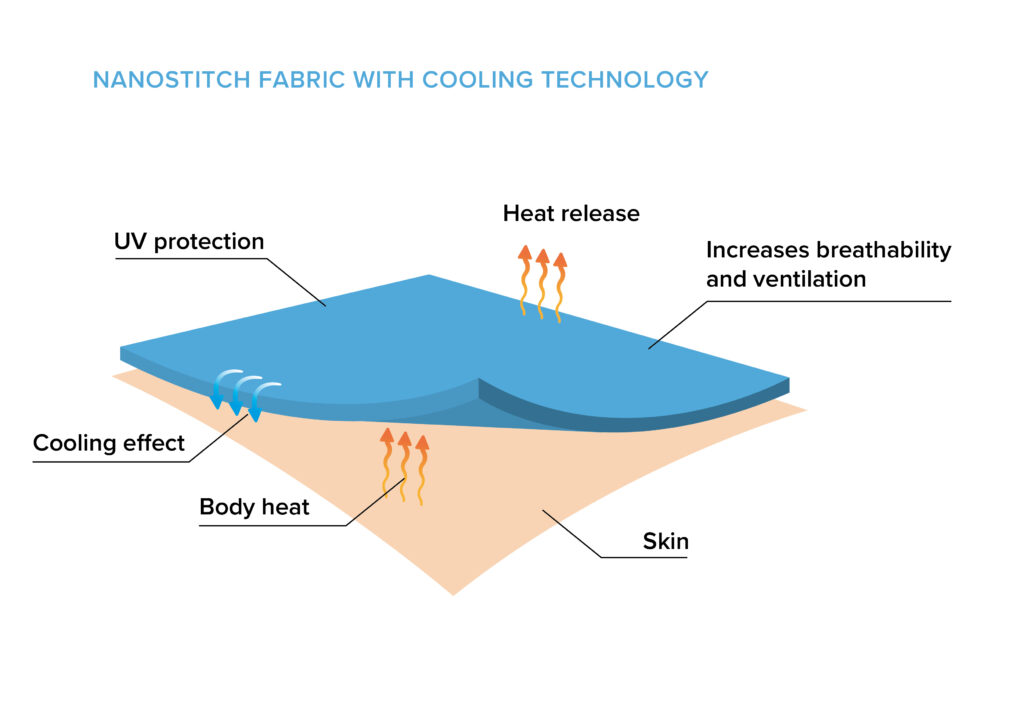

One of the key characteristics of woven mesh cloth is its good air permeability. This means that it allows air to pass through the fabric easily, making it a great choice for hot weather clothing and home textiles. In addition, the fabric is also very cool to the touch, which makes it ideal for use in bedding, towels, and other household items.

Woven mesh cloth can be made in a variety of ways, including white woven or yarn dyed. It can also be made using a jacquard loom, which allows for the creation of intricate patterns and designs. This makes it a popular choice for making curtains, mosquito nets, and other decorative items.

In terms of its durability, woven mesh cloth is generally quite strong and can withstand repeated washing and wear. However, it is important to note that the fabric can be prone to snagging and running, so it should be handled with care to prevent damage.

Overall, woven mesh cloth is a versatile and practical fabric that can be used for a wide range of applications. Its good air permeability, cool texture, and durability make it a great choice for hot weather clothing, home textiles, and industrial uses.

The mesh cloth can be made of pure cotton or chemical fiber blended yarn (thread). The full yarn mesh cloth generally uses 14.6~13 # (40~45 inch count) yarn, and the full yarn mesh cloth uses 13~9.7 # double strand yarn (45 inch count/2~60 inch count/2). The yarn and thread can also be interwoven, which can make the cloth pattern more prominent and enhance the appearance effect.

There are generally two methods for weaving woven mesh: one is to use two groups of warp yarns (ground warp and twisted warp), twist each other to form a shed, and interweave with the weft yarn (see leno weave). Warping refers to the use of a special heald (also called semi heald) that is sometimes twisted on the left side of the ground warp. After one (or three, or five) weft projection, it is twisted to the right side of the ground warp. The mesh shaped holes formed by mutual twisting and weft interweave are stable and called gauze; The other is to use the change of jacquard weave or reeding method. The warp yarn is a group of three and is threaded into a reed tooth. It can also weave fabrics with small holes on the cloth surface, but the mesh structure is unstable and easy to move, so it is also called false leno.

Knitted mesh cloth can be divided into two main types: weft knitted mesh cloth and warp knitted mesh cloth. Warp knitted mesh cloth is typically produced using a West German high-speed warp knitting machine, and is made from raw materials such as nylon, polyester, and spandex. The finished products of knitted mesh cloth include a wide range of mesh fabrics, including high elastic mesh cloth, mosquito net, laundry net, bag net, hard net, sandwich net, kericot, embroidered mesh cloth, wedding net, square net, transparent net, American net, diamond net, jacquard net, and lace. Each type of mesh fabric has its own unique properties and applications, such as high elasticity, breathability, and durability. They are widely used in various industries, including textile, clothing, home textiles, and industrial applications.