1、 Utilize the flexibility of knitted fabrics

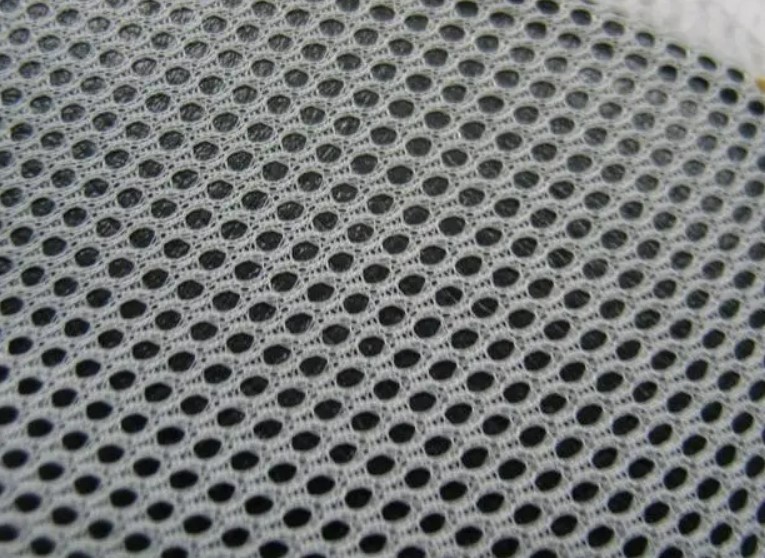

Knitted fabrics have several advantages when it comes to designing and manufacturing clothing. One of the main benefits is their flexibility, which allows for minimal seams, pleats, and splices in the design. This flexibility also makes it possible to create patterns that fit the body curve without the need for pushing back or ironing.

Another advantage of knitted fabrics is that they can be designed to fit the body curve without leaving any slack. This means that the pattern can be created to match the size of the human circumference, or it can be reduced by considering the elastic coefficient of the fabric. This allows for a more tailored fit and a more comfortable wear.

In contrast, woven clothing typically has a larger pattern than knitted clothing, which means that there is more fabric in the garment than necessary to wrap the body. This extra fabric can result in a looser fit and a less comfortable wear.

Overall, knitted fabrics offer several benefits when it comes to designing and manufacturing clothing, including flexibility, a tailored fit, and comfort. These advantages make knitted fabrics a popular choice for many clothing designers and manufacturers.

2、 Utilize the crimping property of knitted fabrics

Curling of knitted fabrics is the phenomenon of edge fabric curling caused by the disappearance of the stress in the fabric edge coil. Curling is the weakness of knitted fabrics. It can cause the unevenness of the seam of the garment piece or the size change of the garment edge, and ultimately affect the overall modeling effect and the size of the garment. However, not all knitted fabrics have crimping property, but only fabrics with individual organizational structures, such as weft knitted fabrics. For this kind of fabric, it can be solved by adding dimensions for edging, inlaying rib or piping, and inlaying adhesive strips at the edge of the garment. The crimping of some knitted fabrics has been eliminated in the process of fabric finishing, which avoids the trouble of pattern design.

It should be pointed out that many designers can turn the disadvantages into advantages on the basis of understanding the fabric performance. They can use the crimping property of the fabric to design it at the neckline and cuffs of the sample, so that the clothing can get a special appearance style, which is refreshing, especially in the weaving of formed clothing, they can also use its crimping property to form a unique pattern or parting line.

3、 Pay attention to the looseness of knitted fabrics

Knitted fabrics have unique characteristics that set them apart from woven fabrics, and their clothing style should be designed to accentuate their advantages while minimizing their disadvantages. One of the main challenges of knitted fabrics is that they can be loose and stretchy, which can make them prone to sagging and losing their shape. To address this issue, designers should avoid using too much exaggeration in the design and production of the pattern, such as excessive darts and cutting lines. Additionally, splicing seams should be used judiciously to prevent the loose knitting coil from affecting the clothing’s wearability.

Instead, designers should focus on creating simple and soft lines that coordinate with the soft and comfortable style of the knitted fabrics. This can be achieved by using basic shapes and clean lines, and by avoiding too much embellishment or ornamentation. The goal is to create clothing that is not only comfortable to wear but also visually appealing and stylish.

In summary, when designing clothing made from knitted fabrics, it’s important to consider the unique characteristics of the fabric and avoid design elements that may accentuate its disadvantages. By using simple and soft lines, designers can create clothing that is both comfortable and stylish, and that showcases the best qualities of the knitted fabric.