Introduction

A textile factory stands as a beacon of innovation and creativity in the world of fabrics. These industrial marvels are where natural and synthetic fibers are magically transformed into the textiles that adorn our lives. From the softness of cotton to the elegance of silk, the versatility of polyester to the strength of nylon, textile factories breathe life into the very fabrics we wear and cherish. In this extensive blog post, we will explore the intricacies of textile factories, the processes they employ, their impact on society and the environment, and the importance of adopting sustainable practices.

1. The Textile Factory Ecosystem

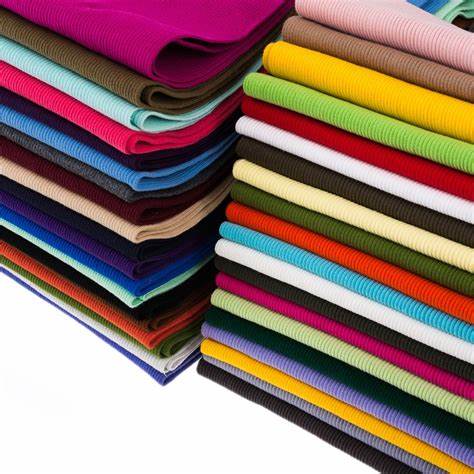

A textile factory is a bustling hub where raw materials are processed into an extensive range of textiles. The heart of this ecosystem lies in the production of fabrics such as cotton, wool, silk, polyester, nylon, and more. Each material brings with it unique properties that cater to diverse consumer needs and preferences. From luxurious silk for elegant occasions to hardwearing polyester for sportswear, textile factories provide an array of options for various market segments.

2. The Marvel of Machines and Processes

2.1 Spinning

At the core of the textile factory’s production process is spinning, the art of transforming raw fibers into yarns. Spinning machines deftly draw out the fibers, twist them together, and create continuous threads of varying thickness and strength. This step lays the foundation for the subsequent stages of textile production.

2.2 Weaving and Knitting

Weaving and knitting are the techniques that bring life to yarns, converting them into intricately designed fabrics. In weaving, vertical threads, known as warp, interlace with horizontal threads, called weft, to form the desired fabric. Knitting, on the other hand, uses needles to create interlocking loops of yarn, resulting in a flexible and stretchable textile.

2.3 Dyeing and Printing

Dyeing and printing are the transformative stages that infuse colors and patterns into the fabrics. Dyeing involves immersing the fabric in dye solutions, while printing uses specialized techniques to apply designs or patterns onto the fabric’s surface. These processes allow for a limitless spectrum of colors and designs to cater to the ever-changing trends in the fashion world.

2.4 Finishing

The finishing process adds the final touches to the fabric, enhancing its feel, appearance, and performance. Finishing may involve treatments like softening, water repellency, flame retardancy, and stain resistance. This stage ensures that the fabric meets the desired standards of quality and functionality.

3. The Impact of Textile Factories

3.1 Economic and Social Significance

Textile factories play a pivotal role in the global economy, driving employment and generating income for numerous individuals. In developing countries, textile factories offer opportunities for skill development and economic growth, lifting communities out of poverty. The clothing produced in these factories serves as a basic necessity, providing comfort, protection, and self-expression to people around the world.

3.2 Environmental Concerns

As with any large-scale industrial process, textile factories have an environmental footprint. Factors like water consumption, pollution from dyeing and finishing processes, waste generation, and energy usage present challenges for sustainability. To address these concerns, the textile industry is continuously exploring and implementing eco-friendly practices, such as water recycling, waste reduction, and the use of renewable energy sources.

3.3 Labor Conditions

The textile industry’s rapid growth has at times been accompanied by concerns about labor conditions, particularly in developing countries. Ensuring fair wages, safe working environments, and ethical labor practices is vital to foster a healthy and responsible textile factory ecosystem. Global initiatives and certifications, such as Fair Trade and SA8000, play a significant role in driving positive change in this regard.

4. Embracing Sustainable Practices

Textile factories bear a responsibility to embrace sustainable practices to minimize their environmental impact and improve operational efficiency. The adoption of eco-friendly technologies, like waterless dyeing and energy-efficient machinery, can significantly reduce the carbon footprint of textile production. Additionally, innovative approaches such as recycling and upcycling of textiles contribute to waste reduction and promote a circular economy.

Conclusion

Textile factories stand at the crossroads of art, science, and commerce, transforming raw materials into the fabrics that adorn our lives. From spinning to finishing, each stage in the production process brings with it a unique blend of creativity and expertise. The economic significance of textile factories cannot be understated, as they provide employment, income, and clothing to countless individuals globally.

However, this grand endeavor is not without its challenges. Environmental concerns, labor conditions, and the need for sustainability require a collective effort from stakeholders across the textile industry. By embracing sustainable practices and fostering responsible operations, textile factories can continue to thrive as guardians of craftsmanship, innovation, and global connectivity. As consumers, designers, and industry leaders, we have the power to shape the future of textile factories and ensure a vibrant and sustainable legacy for generations to come.