Textile manufacturing is a complex and multifaceted industry that plays a fundamental role in our everyday lives. From the clothes we wear to the linens on our beds, textiles are ubiquitous. But have you ever wondered what goes on behind the scenes in a textile manufacturing facility? In this comprehensive guide, we’ll delve into the world of textile manufacturing, exploring the processes, materials, and technologies that drive this essential industry.

Understanding Textile Manufacturing

At its core, textile manufacturing is the process of converting raw fibers into finished textiles. The journey begins with fiber, which can be natural (like cotton, wool, or silk) or synthetic (such as polyester or nylon). These fibers are the building blocks of textiles, and their properties greatly influence the characteristics of the final product.

Fiber to Yarn: Spinning the Threads

The first step in textile manufacturing involves spinning the fibers into yarn. This process is known as spinning and has evolved significantly over the centuries. Traditional methods, like hand spinning, have given way to highly automated and efficient machinery. Spinning transforms the loose, fluffy fibers into continuous strands of yarn, which can be wound onto bobbins or cones.

Yarn to Fabric: Weaving the Story

Once the yarn is ready, the next stage is to convert it into fabric. Weaving and knitting are the two primary methods for achieving this. Weaving involves interlacing two sets of yarn at right angles to create a stable fabric structure. Knitting, on the other hand, forms loops of yarn to create stretchy and versatile fabrics. The choice between these methods depends on the desired texture, strength, and appearance of the fabric.

Dyeing and Printing: Adding Color and Design

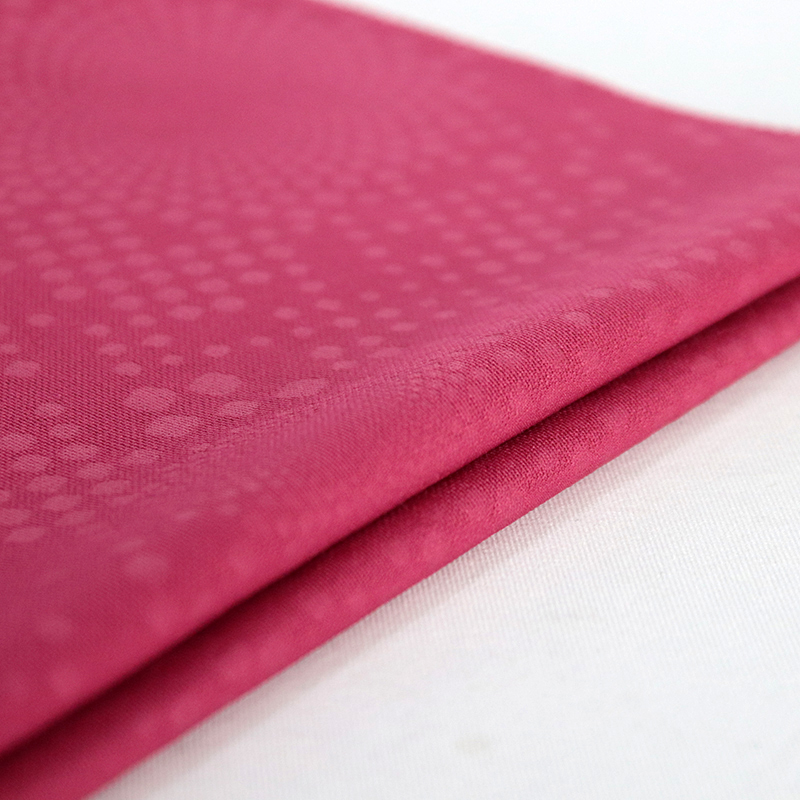

Plain, undyed fabric is transformed into vibrant textiles through dyeing and printing processes. Dyeing involves immersing the fabric in a dye bath, allowing it to absorb the color. Printing, on the other hand, applies patterns or designs to the fabric’s surface using various techniques, such as screen printing or digital printing. These processes give textiles their unique visual appeal.

Fabric Finishing: Enhancing Texture and Performance

Fabric isn’t just about looks; it’s also about feel and function. Fabric finishing processes are employed to improve texture, durability, and performance. Finishing treatments can include processes like mercerization to enhance the fabric’s strength and luster or applying special coatings for water repellency.

Tailoring to Specific Needs

Textile manufacturers don’t just produce fabrics for clothing; they cater to a wide range of industries. The automotive sector relies on textiles for upholstery and interior components. The healthcare industry benefits from specialized textiles used in medical devices and apparel. The home furnishing industry relies on textiles for curtains, upholstery, and bed linens. Each sector has its unique requirements, driving innovation in textile manufacturing.

The Role of Sustainability

In recent years, sustainability has become a paramount concern in textile manufacturing. Many manufacturers are adopting eco-friendly practices, such as using organic and recycled fibers, reducing water and energy consumption, and implementing responsible dyeing and finishing processes. Sustainable textiles are not only good for the environment but also appeal to consumers who are increasingly conscious of their ecological footprint.

Technological Advancements

The textile manufacturing industry has witnessed remarkable technological advancements. Automation and digitalization have revolutionized the production process, leading to increased efficiency and precision. Computer-aided design (CAD) and computer-aided manufacturing (CAM) systems have streamlined the creation of intricate fabric patterns and the operation of textile machinery.

Quality Control and Testing

Quality control is an integral part of textile manufacturing. Manufacturers conduct rigorous testing to ensure that fabrics meet industry standards for strength, colorfastness, and durability. This involves subjecting fabrics to various tests, including tensile strength tests, colorfastness tests, and abrasion resistance tests. Quality control measures help maintain consistent product quality.

Conclusion: The Fabric of Our Lives

In conclusion, textile manufacturing is a dynamic and vital industry that touches every aspect of our lives. From the clothes we wear to the materials used in our homes and workplaces, textiles are an integral part of our daily experience. Understanding the intricate processes involved in textile manufacturing sheds light on the craftsmanship and innovation that go into creating the fabrics we rely on. As sustainability and technology continue to shape the industry, the future of textile manufacturing holds exciting possibilities, ensuring that we will continue to be surrounded by high-quality, sustainable, and aesthetically pleasing textiles for years to come.