Textiles are an integral part of our daily lives, from the clothes we wear to the linens in our homes and the technical fabrics in the industries we rely on. But have you ever wondered about the processes, responsibilities, and innovations behind textile manufacturing? In this comprehensive exploration, we will unravel the world of textiles manufacturing, shedding light on the crucial role of textiles manufacturers in shaping our material world.

Introduction to Textiles Manufacturing

Definition and Overview

Textiles manufacturing refers to the complex and multifaceted process of converting fibers into finished textiles. These textiles, which include fabrics of various types, serve as the foundation for a wide range of products, from clothing and home furnishings to technical materials used in aerospace and healthcare.

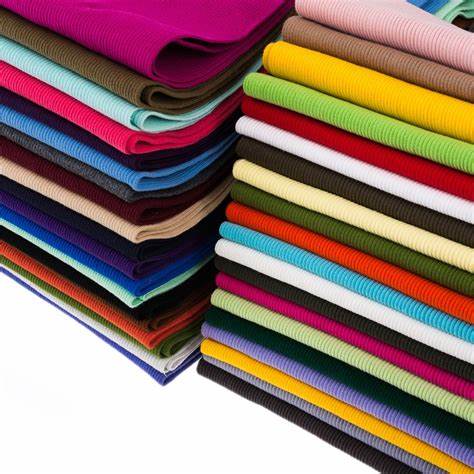

The journey of textile manufacturing begins with raw fibers, which can be natural, such as cotton, wool, or silk, or synthetic, like polyester or nylon. These fibers are the fundamental building blocks of textiles, and their characteristics influence the properties of the final product.

Importance of Textiles Manufacturing

The importance of textiles manufacturing cannot be overstated. It is a critical sector that intersects with numerous industries and aspects of our lives. Textiles are not just about fashion and comfort; they also play a vital role in sectors like healthcare, automotive, and construction. The quality, performance, and sustainability of textiles impact the products we use and wear daily.

The Role of a Textiles Manufacturer

Manufacturing Process

Textiles manufacturing involves a series of intricate processes, each with its own set of challenges and requirements. These processes include spinning fibers into yarn, weaving or knitting yarn into fabric, dyeing and printing to add color and design, and various finishing processes to enhance texture and performance.

The role of a textiles manufacturer encompasses overseeing and optimizing each of these stages to ensure the production of high-quality textiles. This requires expertise in material science, production technologies, and quality control.

Key Responsibilities and Functions

Textiles manufacturers are responsible for several critical functions. They must source and manage raw materials, ensuring the availability and quality of fibers. They also operate and maintain a range of specialized machinery, from spinning frames to looms and dyeing equipment.

Moreover, manufacturers must have a deep understanding of design principles and aesthetics. They collaborate closely with designers to bring creative visions to life, and with suppliers to procure the necessary materials. Effective logistics and supply chain management are crucial to ensure timely production and delivery.

Collaboration with Designers and Suppliers

Collaboration is a cornerstone of textiles manufacturing. Textiles manufacturers work in tandem with designers to realize creative concepts. Designers provide input on fabric textures, patterns, and colors, which manufacturers must translate into tangible products.

Manufacturers also collaborate with suppliers to secure a steady supply of fibers and other materials. These partnerships are essential to maintain consistency in product quality and meet production deadlines.

Types of Textiles Manufacturers

Textiles manufacturing is a diverse field with various specializations. Manufacturers can be broadly categorized into the following types:

Apparel Manufacturers

Apparel manufacturers focus on producing textiles for the fashion industry. They create fabrics for clothing, including everything from casual wear to haute couture. Apparel manufacturers need to stay attuned to fashion trends and consumer preferences to remain competitive.

Home Textiles Manufacturers

Home textiles manufacturers produce fabrics for household items such as bed linens, curtains, and upholstery. They prioritize factors like comfort, durability, and aesthetics to meet the demands of the home furnishings market.

Industrial Textiles Manufacturers

Industrial textiles manufacturers specialize in producing fabrics for industrial applications. These textiles may be used in conveyor belts, filtration systems, or automotive components. Durability and functionality are paramount in this sector.

Technical Textiles Manufacturers

Technical textiles manufacturers produce fabrics with specific technical properties. These textiles find applications in areas like aerospace, healthcare, and geotextiles for construction. Precision and performance are critical in technical textiles manufacturing.

Textiles Manufacturing Techniques and Technologies

Textiles manufacturing relies on a range of techniques and technologies to produce diverse fabrics. Some of the key methods include:

Weaving and Knitting

Weaving involves interlacing two sets of yarn at right angles to create a stable fabric structure. Knitting, on the other hand, forms loops of yarn to create stretchy and versatile fabrics. The choice between these methods depends on the desired texture, strength, and appearance of the fabric.

Dyeing and Printing

Dyeing and printing processes transform plain, undyed fabric into vibrant textiles. Dyeing immerses the fabric in a dye bath, allowing it to absorb color, while printing applies patterns or designs to the fabric’s surface using various techniques. These processes give textiles their unique visual appeal.

Finishing Processes

Fabric finishing processes are employed to improve texture, durability, and performance. Treatments can include processes like mercerization to enhance strength and luster, or applying special coatings for water repellency. These enhancements make fabrics more functional and versatile.

Automation and Innovation in Textiles Manufacturing

Advancements in technology have revolutionized textiles manufacturing. Automation, digitalization, and robotics have increased efficiency and precision. Computer-aided design (CAD) and computer-aided manufacturing (CAM) systems have streamlined the creation of intricate fabric patterns and the operation of textile machinery.

Quality Control and Compliance in Textiles Manufacturing

Ensuring Product Quality

Quality control is paramount in textiles manufacturing. Manufacturers conduct rigorous testing to ensure that fabrics meet industry standards for strength, colorfastness, and durability. This involves subjecting fabrics to various tests, including tensile strength tests, colorfastness tests, and abrasion resistance tests.

Compliance with Industry Standards and Regulations

Compliance with industry standards and regulations is a crucial aspect of textiles manufacturing. Textiles must meet safety and quality standards to ensure consumer protection. Manufacturers must stay up-to-date with evolving regulations and incorporate them into their processes.

Sustainable Practices in Textiles Manufacturing

In recent years, sustainability has become a driving force in textiles manufacturing. Many manufacturers are adopting eco-friendly practices, such as using organic and recycled fibers, reducing water and energy consumption, and implementing responsible dyeing and finishing processes. Sustainable textiles not only benefit the environment but also appeal to consumers who prioritize ethical and eco-conscious products.

Global Textiles Manufacturing Hubs

Overview of Major Manufacturing Regions

Textiles manufacturing is a global industry with significant production hubs in various regions. Asia, particularly China and India, has emerged as a dominant force in textiles manufacturing due to its abundant labor force and resources. Other regions like Europe and the Americas also have thriving textile industries, each with its unique strengths and specialties.

Comparative Analysis of Manufacturing Hubs

Different manufacturing hubs have their advantages and challenges. For example, while Asia offers cost-effective production, it may face issues related to quality control and supply chain disruptions. European manufacturers often excel in high-end fashion textiles and sustainable practices. American manufacturers prioritize innovation and automation.

Challenges and Trends in Textiles Manufacturing

Supply Chain Management

Managing complex global supply chains is a major challenge in textiles manufacturing. Manufacturers must ensure a steady supply of raw materials, navigate trade regulations, and address issues like transportation and logistics.

Technological Advancements

The textiles industry continues to evolve with technological advancements. Innovations like 3D knitting and smart textiles are reshaping the possibilities of what textiles can do. These advancements enhance functionality and open new avenues for product development.

Sustainable and Ethical Manufacturing Practices

Consumers are increasingly conscious of sustainability and ethical practices. Textiles manufacturers are responding by adopting eco-friendly materials, reducing waste, and ensuring fair labor practices throughout the supply chain. Sustainability isn’t just a trend; it’s a fundamental shift in the industry.

Market Trends and Consumer Preferences

Changing consumer preferences, influenced by factors like fast fashion, e-commerce, and sustainability, are driving shifts in textiles manufacturing. Manufacturers must adapt to these trends to remain competitive in a dynamic market.

Conclusion

Recap of Textiles Manufacturing

In summary, textiles manufacturing is a vast and intricate industry that touches every aspect of our lives. Textiles manufacturers are the architects of the fabrics that define our world, from the clothes we wear to the products we use. They navigate a complex landscape of materials, processes, and technologies to deliver textiles that meet our diverse needs.

Future Outlook and Opportunities

The future of textiles manufacturing holds exciting opportunities and challenges. Sustainability will continue to be a driving force, pushing manufacturers to innovate in materials and processes. Technology will open new frontiers, enabling the creation of textiles with unprecedented properties. As consumer preferences evolve, textiles manufacturers must remain agile and adaptable to thrive in an ever-changing market.

In conclusion, textiles manufacturing is a dynamic and essential industry that weaves the fabric of our lives. It is a testament to human creativity and ingenuity, and its future promises continued innovation and progress.